Singapore Laser Welding Technology for the Jeweler Trade

A Good Deal of jewellers Believe It Is Impossible to repair or resize items of jewelry made from metals like stainless steel or ceramic. Well, it is tough to find someone to repair them with a laser welder the job is simple. The issues that jewellers have in Resizing rings with soft stones like coral, pearl, opal and several others are that they will be immediately destroyed by heat from a jeweler’s torch. Diamonds, rubies and sapphires may have a jeweler’s flashlight actually touch them and they would not break. Obviously this is always avoided if at all possible. But many different stones, even emeralds, will need to be taken out of the ring so that the heat from the flashlight may be used to solder two components together.

That presents a further problem when The stones have been bezel set. Bezel setting entails the alloy being forced over the rocks and pushed and rubbed over. This is a 1 way action and you cannot prize the metal back, take out the rock, and after the soldering was done, replace the rock and then push the bezel metal over it. This metal is now destroyed. So what if you can leave the stone Set up and cut the ring and remove a bit which makes the ring a smaller size and then solder it back together again? Well, that would be just perfect and you can certainly do this with laser technology.

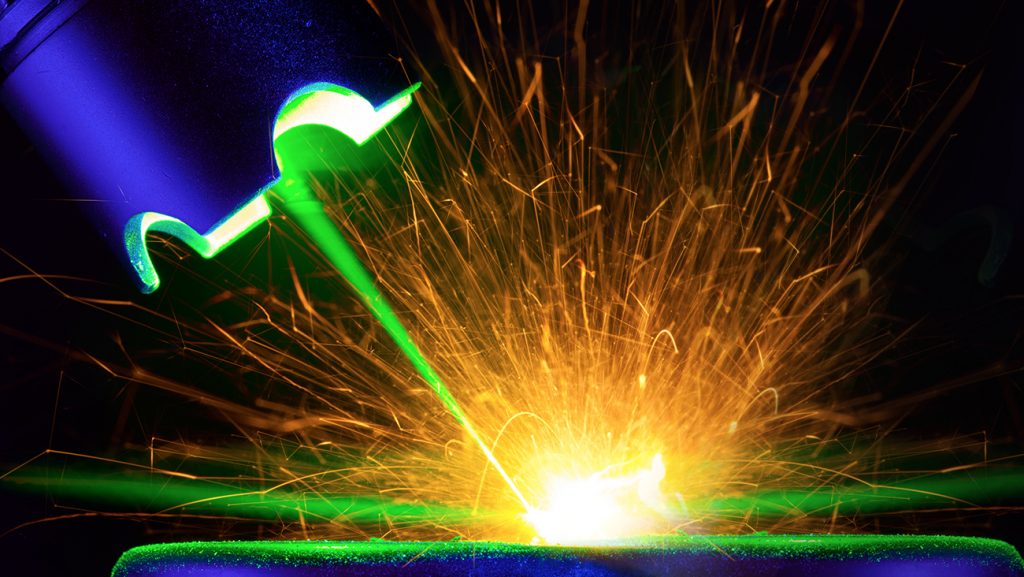

Having a laser welding singapore machine that Currently costs between $30,000 and $50,000 you can leave the rock in place and create the resize and then fuse or weld the two pieces together. The reason that this could be done successfully is because the laser only creates a small bit of heat. It is possible to hold the ring in your hand and laser weld it together. Lasers can be used on all types of Metals titanium, stainless steel, silver, platinum and gold. The laser weld is in fact a combination of the two metal parts so no solder or cluttered flux is used. The weld is three times more powerful than the greatest soldered joints. Tiny pieces can be welded together as Small as 0.2 of a millimeter and that is small. Most white gold is rhodium plated to give it this shiny white look but if it is repaired it must be rhodium plated once more but not with laser technology as the weld is a really localized one.